In 2013 we embarked upon a £5m refubrishment of our Loughborough factory.

The projects scope was vast with the overall objective of making our facilities world class.

The project included:

- Floor fully re-laid

- Air movers to facilitate stress-free movement of transformers

- Test areas refurbished

- Sound enclosure installed to allow interference free noise testing

- Increased lifting capacity to 100 tonnes

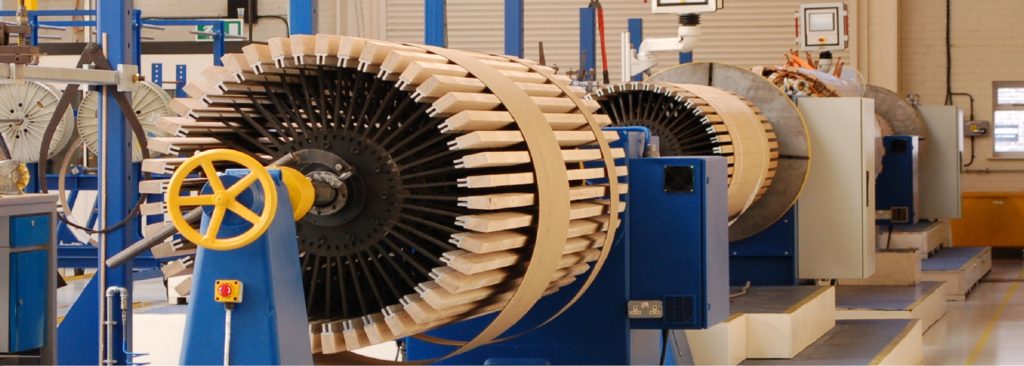

- In-house manufacture of 40MVA 115kV test transformer specially designed for variable loading conditions with frequent switching cycles

- Relocation of Tapchanger production line

- New vacuum oven

- New oil processing plants with improved storage

- New canteen area and production offices

The end result has given us a remarkable facility to perfectly complement our position as world class manufacturers of Transformers and Tapchangers.