Geothermal power production is a form of renewable energy generation that harnesses thermal energy from underground sources.

Boreholes are drilled into the geothermal source and water is injected at pressure to be heated. The water returns in the form of steam, which is used to drive geothermal steam turbines. The driver in turn, rotates a generator which produces electrical power.

The thermal energy must be of a certain temperature to be suitable for power generation, and the location of the energy sources meeting this requirement are often in environmentally challenging locations.

The Challenge

BRUSH was asked to provide generators for a location in Chile specially adapted for extreme conditions. The location of the site was at high altitude in the Atacama Desert at 4,500m. At these altitudes the air is much thinner and had high levels of hydrogen sulphide (H2S) and sulphur dioxide (SO2) gases. We called on our long experience in designing engineered solutions for generator applications to meet this challenge.

The Solution

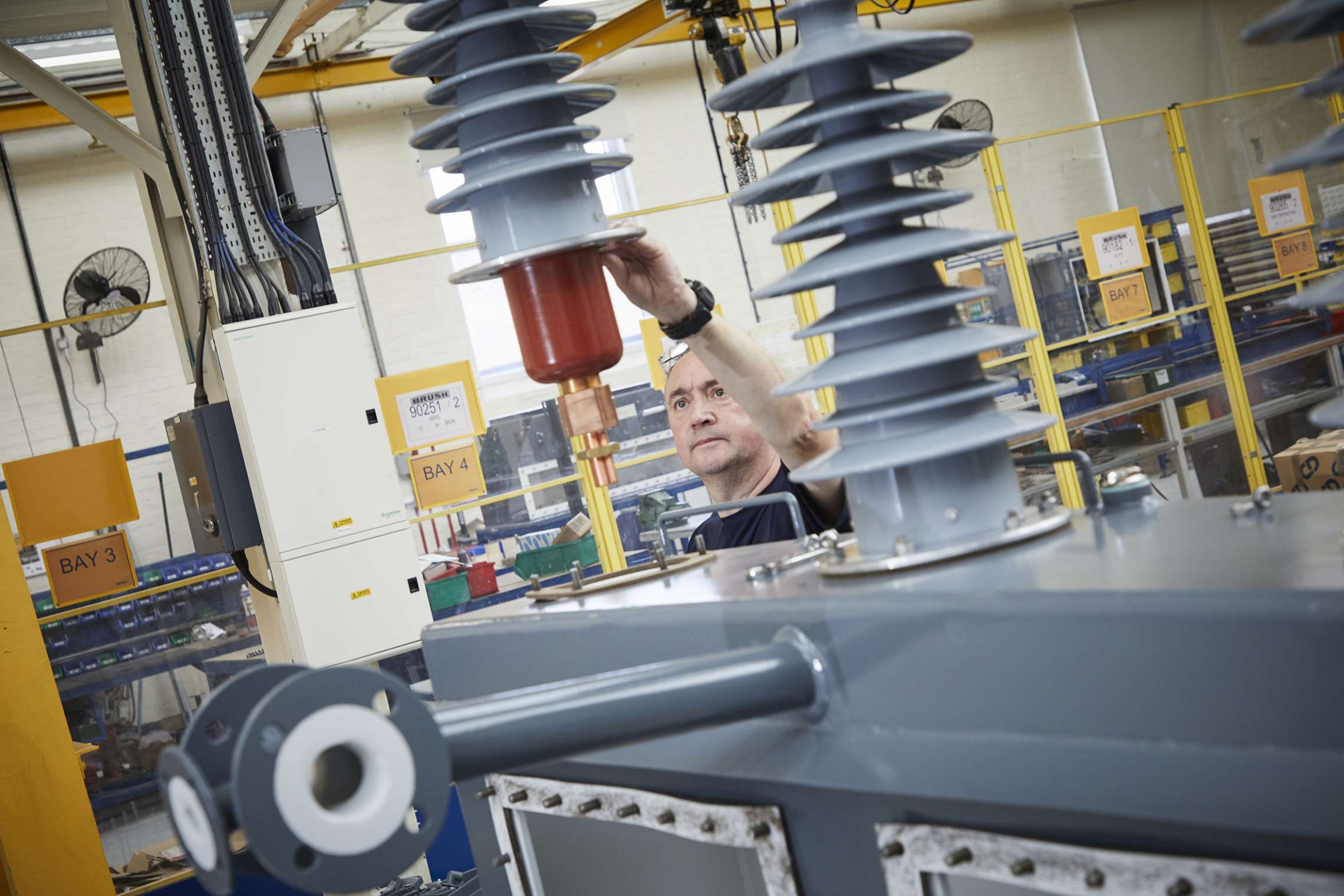

Ensuring the equipment used to produce the power could endure harsh elements was imperative, so we supplied two specially modified, 27.6MW, four-pole, 1,500r/min generators with a rated voltage of 9,500V and a power output of 32.5MVA. Each of the dual-shaft generators were powered by two 15MW turbines and designed to withstand the challenges presented by extracting geothermal energy in 4,500m conditions.

At high altitudes the air is much thinner which can increase the potential for damaging partial discharge activity in the stator winding.

Our design team developed a solution that de-rated the generation voltage to reduce the risk of stator damage, while maintaining the specified power output. This means that the generators will be kept online by optimising the stress on the electrical insulation system

We evaluated solutions for generator cooling due to the thinner air, this was complicated by both the ambient temperatures at extremes lows of -31°C, and the presence of toxic H2S and SO2 gases.

To counter these threats, we designed a pressurisation system that provided clean air to the inner part of the generators and that featured a special filtration system to neutralise the H2S and SO2 gases. Specialized heating was installed to keep the generator warm during times when the system was idle.

This application location also presented human challenges. Service personnel could only be present at such extreme altitudes for short periods of time without suffering from altitude sickness. This meant installation, and later maintenance, had to be carefully planned and scheduled with the operator. Strict guidelines were put in place to ensure the safety and health of the team.

The Result

We completed the design and build within the agreed delivery lead time, and power output specification. In doing so, we contributed to the first power plant built at this altitude worldwide, increasing the number of locations that can be considered for geothermal energy production.

When you have a challenging power generation application contact BRUSH to discuss our solutions.